Classification Of Nanocomposites Ppt. When strong wind gusts bend the blades the nanocomposite will also bend. These systems require controlled mixingcompounding stabilization of the. Compared to a film made with conventional composites the water drop would face more barrier going through the film made with nanocomposites because the distance between fillers is much smaller. Nano-nanocomposites Ceramic nanocomposites Metal-Nanopolymer composites Polymer nanocomposites.

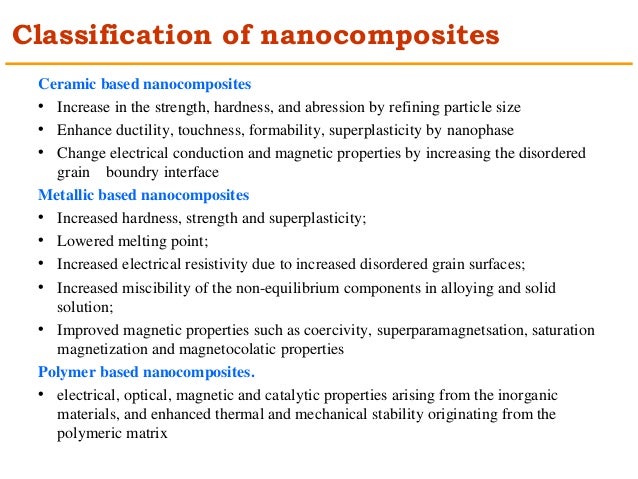

Nanocomposites are used in a range of industries. Classification of Nanomaterials The classification of nanomaterials is based on the number of dimensions which are in nano range 100 nm. Nanocomposite is a multiphase solid material where one of the phases has one two or three dimensions of less than 100 nanometers or structures having nano-scale repeat distances between the different phases that make up the material. This property allows patches of polymer-nanotube nanocomposite to act as stress sensors on windmill blades. InorganicOrganic Hybrid Nanocomposites Nanocrystal Eg. Nanocomposites comprise multiphase materials such as metals polymers inorganic ceramics where at least one constituent has one dimension less than 100nm.

Therefore nanocomposites promise new applications in many fields such as mechanically-reinforced lightweight components non-linear optics battery cathodes and ionics nanowires sensors and.

Compared to a film made with conventional composites the water drop would face more barrier going through the film made with nanocomposites because the distance between fillers is much smaller. In this chapter the fabrication of three types of nanocomposites based on the biocompatible electrospun hydrogels namely. 1 or more phases 100nm Properties unachievable with traditional materials Types of nanocomposites. Nanocomposites are composites in which at least one of the phases shows dimensions in the nanometre range 1 nm 10-9 m 1. When strong wind gusts bend the blades the nanocomposite will also bend. When the layers or grains in the nanocomposite are in nanometer range superlattice effects may further improve the properties of the coating 19.