Compressed Air System In Power Plant. Compressed air systems are key components at hydroelectric power plants. Its used to control the speed of the engine by changing the fuel provide according to engine load. The progressive thinking here is If you dont use the energy to produce electric power you can sell it. Essentially the term compressed air energy storage outlines the basic functioning of the technology.

Compressed air at a power plant finds application in coal handling operating pneumatic instruments connected with boilers turbines generators precipitators and ash handling system. M a h a d i H a s s a nGoverning system. Taking a systems approach can help eliminate ongoing system problems. General applications include purging and driving pneumatic tools. It is used for other. The demand for compressed air may vary significantly at the plant.

The compressor used in power plant is a two staged reciprocating type.

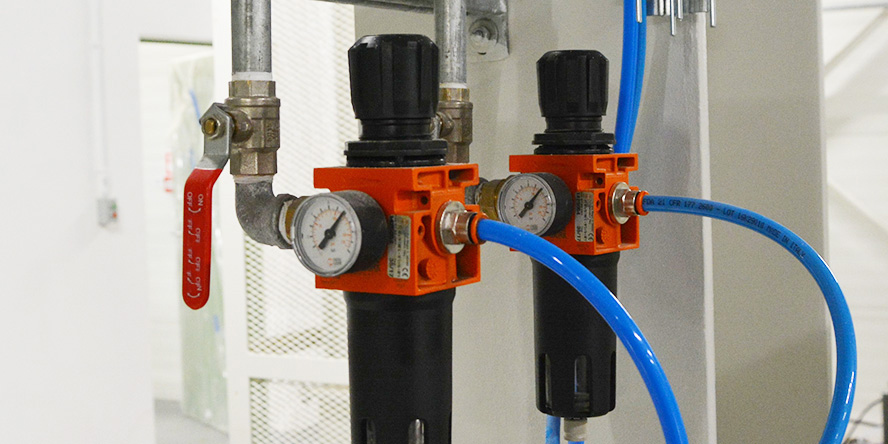

Compressed air is safe economical adaptable easily transmitted and provides labor saving power. On a recent compressed air audit at a Midwestern power plant we developed the following data profile. One is instrument air and the other is service air. The first industrial compressors were. Air compressors are used to get the compressed air. Compressed air is commonly also used at lower pressures to control the engine and act as the spring force acting on the cylinder exhaust valves and to operate other auxiliary systems and power tools on board sometimes including pneumatic PID controllers.