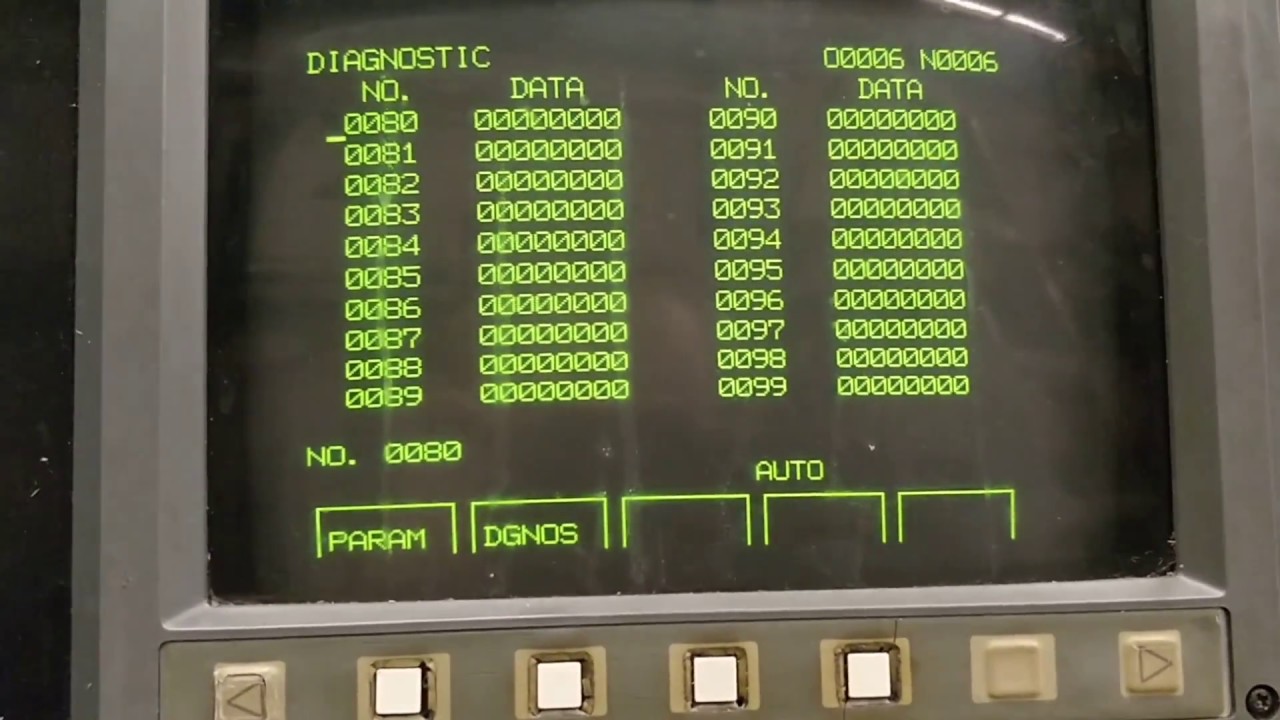

Fanuc Tool Change Parameters. Dont panic when you get one of. Weve got an long turning center. Also used extensively in horizontals where g30 usually gets set as the point the head travels to during tool change etc. Turn on PWE Parameter Write make it a 1 Press the function Hard key SYSTEM.

We work like that for years and we have no issuesthere is more to tell butno time for typinglol. The above parameter 5013 means that the maximum amount you could have in the wear offset is 3. Parameter number new parameter value and select input type. Maximum Wear Offset Fanuc Parameter. We have 28 Fanuc Parameter manuals for free PDF download. Place a tool holder in the tool change mechanism.

We work like that for years and we have no issuesthere is more to tell butno time for typinglol.

Maximum Wear Offset Fanuc Parameter. Perform a manual Zero Return operation or execute G91 G28 Z00 via MDI. Place a tool holder in the tool change mechanism. May need to page up or down to get to the top of the Parameter numbers. We work like that for years and we have no issuesthere is more to tell butno time for typinglol. With the G73 peck drilling retract amount for example it may be necessary to use a setting of 0005 inch for one cutting tool in a program and 0010 inch for another.