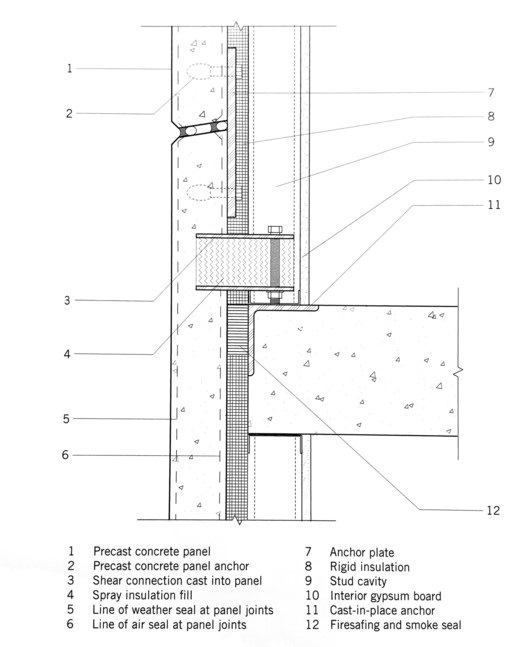

Precast Concrete Panel Construction Details. Professionalism in Australian concrete construction. This can easily be increased by selecting foam of 80mm or 100mm. In precast concrete construction majority of structural members are manufactured in manufacturing plants away from the construction site. Steel stud wall panel wall system 1 Figure 15.

Caucasian region of Russia etc. Design Details Home Design Architectural Resources Design Details This section provides information and resources related to design of precast concrete systems as well as integration of precast with other systems. Wall panels can be ribbed to increase their vertical span capacity while minimizing weight or formed into other special shapes below. Bsi 054 Risky Business High Risk Walls Wall Section Detail Precast Concrete CladdingBsi 054 Risky. Compare to site construction Quality control of Precast Products is Very Good. They consist of two wythes of factory-manufactured.

Design Details Home Design Architectural Resources Design Details This section provides information and resources related to design of precast concrete systems as well as integration of precast with other systems.

Professionalism in Australian concrete construction. Suggestions for detailing typical architectural precast concrete panel joints figure 1 include. Wall panels can be ribbed to increase their vertical span capacity while minimizing weight or formed into other special shapes below. - Use precast concrete as large format panels on the exterior actingas the exterior finish and structural component that provides the enclosure support function that is they collect wind and self-load and transfer it to the primary structure. These typical Litecrete attachment details have been developed to cope with typical residential panel installations in Climate Zone 1 where the 220 mm thickness complies with the Building Code insulation requirements for concrete and masonry. Precast columns are usually two stories high.