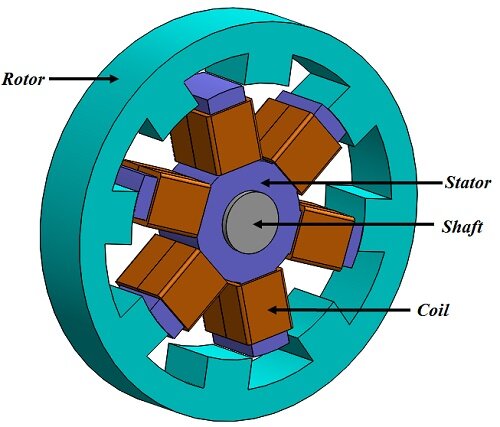

Switched Reluctance Motor Design. Switched reluctance motors provide a distinct advantage in their simplicity of design. When the two electromagnets are energized the rotor will experience a very strong force to align with the magnetic field. There is no winding or permanent magnet on rotor Stator windings on diametrically opposite poles are connected in series or parallel to form one phase of the motor. Because of their simplicity and structural strength SRMs have been.

Nidec manufactures rugged switched reluctance motors under our US. The first designs of this type of motor depended on cage windings in order to function which limited severely its electromagnetic design. EMS Simulation of the In-Wheel Switched Reluctance Motor. The switched reluctance motor working principle is fundamentally the action of the rotor to form a. The following figure has shown the design of a three-phase switched reluctance motor. Manufacturers of switched reluctance motors claim that they can outperform standard induction motors in speed torque reliability and robustness.

Our talented engineering teams can design.

In references 1 8 authors indicates the design of exterior rotor and analyzing the design with the finite element method. This development is partly due to. What is Switched Reluctance Motor. The power_SwitchedReluctanceMotor example illustrates the simulation of the Switched Reluctance Motor. When the two electromagnets are energized the rotor will experience a very strong force to align with the magnetic field. The following figure has shown the design of a three-phase switched reluctance motor.